Introduction

Cranes have long been an integral part of construction projects, and as technology advances, their capabilities and efficiency have improved significantly. In precast construction, cranes are crucial in assembling high-rise buildings and other structures. In this article, we will explore the latest advancements in crane technology and discuss how these innovations are transforming the precast industry.

Crane Technology in the Precast Industry

In the precast concrete industry, cranes play a central role in the productivity and efficiency of precast facilities. Here are some technical aspects of crane technology in the precast industry:

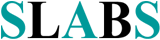

- Types of Cranes

The precast industry uses different types of cranes to meet its lifting needs, including overhead cranes, gantry cranes, and rubber-tyred gantry cranes.

Fig 1: Types of Cranes

Courtesy: LinkedIn

-

- Gantry Cranes: Gantry cranes are a great choice for handling prefabricated products, including concrete pipes, concrete slabs, concrete precast panels, steel and sheet piles, concrete piles, wall panels, core panels, etc. In the precast yard, two gantry cranes can be used to lift the precast beams or a single gantry crane equipped with double hoists can be used.

- Overhead Cranes: The factory uses overhead cranes to handle finished precast elements or bagged premixes.

- Rubber Tyred Gantry Cranes: Rubber tyred gantry cranes are used for the internal transport of precast concrete elements.

- Lifting Precast Concrete Elements

Different types of cranes are used to meet its lifting needs during the production, storage, internal transport, transfer, and construction of precast concrete elements.

- Planning and Safety

The care and time taken by cranes and crew to plan the lift of each piece and shift it to its final position is critical in determining that construction schedules do not trump safety.

Height and Weight Limitations of The Crane

A crane’s height and weight limitations depend on various factors, including the crane’s configuration, structural limitations, distance to the load to be lifted, the height of the lift, ground conditions, and ambient weather conditions.

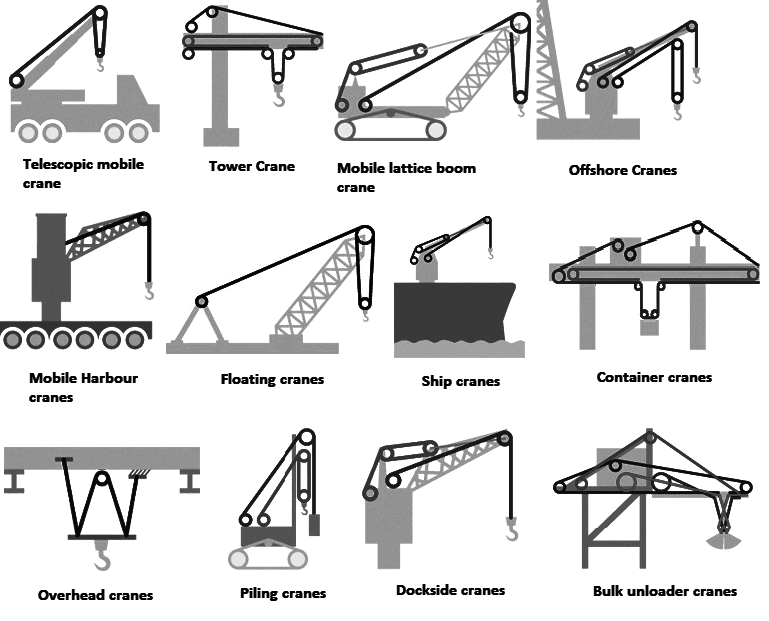

Fig 2: Cranes listed by Capacity

Courtesy: American Cranes and Transport

A typical tower crane has the following specifications:

- Maximum unsupported height: 265 feet (80 meters). The crane can have a total height much greater than 265 feet if tied into the building as it rises around the crane.

- Maximum reach: 230 feet (70 meters)

- Maximum lifting power: Around 19.8 tons (18 metric tons, or tonnes), 300 tonne-meters

- Counterweights: 20 tons (16.3 metric tons).

- Maximum load: As for weight, a crane’s maximum rated capacity usually refers to the maximum net load it can lift under ideal conditions (shortest boom length, minimum lift radius, optimum lift angle, outriggers extended, etc.). The exact weight that a crane can lift depends on the type and model of the crane. The maximum load the crane can lift is 18 metric tons (39,690 pounds), but the crane cannot lift that much weight if the load is positioned at the end of the jib. The closer the load is to the mast, the more weight the crane can lift safely.

Brands of Tower Cranes and Mobile Cranes

There are several brands in the market that manufacture tower cranes and mobile cranes. Some of the top global crane brands include Liebherr, Cargotec, Konecranes, Manitowoc, and Palfinger. Some of India’s top mobile crane manufacturers include Action Construction Equipment (ACE) and ELESTAR Crane System.

Tower Cranes:

- Shanghai Pangyuan Machinery Rental: This is the world’s largest tower crane-owning company.

- NFT: This company is ranked second in the world.

- Liebherr Tower Crane Division: Liebherr is a well-known brand in the crane industry.

- Uperio: This company is ranked fourth in the world.

- Tat Hong Equipment Service: Based in China, this company is ranked fifth globally.

- Morrow Equipment: Based in Oregon, USA, this company has retained its sixth position from 2020.

- Wolffkran: This Switzerland-based company retains its place in seventh.

- Maxim Crane Works: Holding the eighth position on this year’s Index with a total of 148,290 tonne-metres.

- Van der Spek: Netherlands-based company that has risen to ninth, up one place from 2020.

- Neremat: Belgian independent supplier Neremat provides all rental and sales of top-slewing and self-erecting cranes.

Mobile Cranes:

- Action Construction Equipment (ACE): Established in 1995, ACE Equipment Company is a renowned construction equipment company in the Indian market.

- ELESTAR Crane System: Incorporated in 2011, ELESTAR Crane System is the fastest-growing start-up company based in Pune.

- Hydrolift Cranes: Over decades old, Hydrolift Cranes are the pioneers in manufacturing truck-mounted cranes in India.

- Komatsu: A well-known brand used in the construction industry.

- Caterpillar: Another renowned brand used in the construction industry.

These companies have been recognized for their quality products and services in the crane industry.

Impact on the Precast Building Industry

The precast concrete industry is largely dominated by government-initiated projects for infrastructural development. However, these are also being extensively used for residential (low and high rise) and commercial constructions because of their various favorable attributes. The efficiency, durability, ease, cost-effectiveness, and sustainable properties of these products have brought a revolutionary shift in the time consumed in the construction of any structure.

The global precast concrete market size was USD 114.78 billion in 2020 and is projected to grow from USD 118.48 billion in 2021 to USD 159.85 billion in 2028, at a CAGR of 4.4% during the 2021-2028 period. The sudden rise in CAGR is attributable to this market’s demand and growth returning to pre-pandemic levels once the pandemic is over.

However, the COVID-19 pandemic has had a significant impact on the building & construction industry, leading to a slowdown in raw material production, supply chain disruptions, restrictions on man and material movement, and disturbances in trade movements. The pandemic has reduced the demand for precast products resulting in overcapacity.

Despite these challenges, the prefabrication method brings benefits compared to the conventional method and may be an alternative as it has more positive global impacts on the environment, the economy, and society. However, there are some limitations that have been reported and that should be looked into in the future.

Advancements in Crane Technology

There have been several advancements in crane technology that integrate smart tech. Here are some of the key advancements:

- Modular and Adaptable Design: New cranes are modular, adaptable, and intelligent. They are more compact and energy-efficient, eventually rendering legacy systems obsolete.

- Intelligent Modules: Some new cranes offer robust, intelligently designed modules that can be easily configured to meet various needs. Users can change or add new features depending on their business needs. Additional features could include remote diagnostics, maintenance monitoring, or automated positioning.

- Remote Monitoring: Some new cranes have intelligent service panels, allowing operators to diagnose and correct faults quickly. The crane detects its condition automatically and communicates it to the operator via the service panel.

- Load Sensors: Load sensors greatly reduce problems such as shock loading, side loading, side pulls, and overloads.

Fig 3: Sensors in Cranes

Courtesy: Researchgate

- Variable Frequency Drives (VFDs): VFDs have led to several advancements in the crane industry. They help reduce mechanical crane stress and have enabled the development of smart features such as anti-skew technology, sway control, and regenerative braking.

- Comansa’s Advanced Crane Technology: Comansa offers an extensive range of tower cranes for any project involving construction, infrastructures, mining, energy, etc. They have developed Crane Mate, a new digital solution for fleet management and crane monitoring. Comansa’s flat-top cranes have several series with highly interchangeable tower and jib sections, drastically increasing customer configuration possibilities.

- AI and IoT Technologies: AI and IoT technologies are being used to optimize crane efficiency. For example, Versatile’s CraneView™ system is powered by an IoT sensor device mounted to the crane hook. It collects and analyzes data on the flow and handling of materials, production rates, and crane utilization.

Future Scope of Crane Technology in Precast Buildings

The future of crane technology in the precast building industry is expected to be influenced by several factors:

- Increased Mechanization: Precast building constructions are being done with highly mechanized technology, which can finish the entire 10-12 storey buildings in all respects within 5-6 months of time. This increased mechanization will likely lead to advancements in crane technology to keep up with the pace of construction.

- Lorry Loaders: Innovative technologies like the Hiab Loader allow for efficient, safe movement and installation of precast panels. Rather than needing a crane or a second vehicle on-site to unload the lorry and an additional team to install the sections, this crane can easily lift and move the panels into position.

- Standardization: Efforts are being made to introduce a precast Australian Standard for construction materials to deal with the potential knowledge gap when two industries cross over — in this case, the crane industry and the precast construction industry. This standardization could lead to new developments in crane technology tailored specifically for precast construction.

Conclusion

Advanced crane technology is transforming the precast industry by enabling the efficient assembly of high-rise buildings and other structures. The ability to lift heavy precast elements to remarkable heights and with increasing tonnage capacity has revolutionized construction practices. Brands like Liebherr, Manitowoc, Grove, and others continue to push the boundaries of crane technology, ensuring the future of construction is safer, more efficient, and more environmentally friendly. As technology continues to evolve, the precast industry will undoubtedly benefit from these innovations, further streamlining the construction of tall and complex buildings.

References

- https://www.konecranes.com/discover/innovations-in-crane-technology

- https://www.comansa.com/en

- https://www.comansa.com/en/comansa

- https://steelmillcranes.com/precast-concrete-industry/

- https://infrastructuremagazine.com.au/2019/09/11/the-knowledge-gap-for-cranes-and-precast-construction/

- https://precast.org/wp-content/uploads/docs/PCPS_Intro.pdf

- https://www.ijert.org/research/review-of-precast-concrete-technology-in-india-IJERTV10IS060400.pdf

- https://www.internationalcranes.media/news/top-10-tower-crane-companies-2021/8014835.article

- https://gruasyaparejos.com/en/construction-crane/crane-manufacturers/

- https://www.internationaljournalssrg.org/IJCE/2020/Volume7-Issue7/IJCE-V7I7P102.pdf