Modular construction is no longer a buzzword as it’s rewriting how cities are built. By shifting much of the work into factories, it promises faster timelines, lower costs, greener outcomes, and streamlined transportation.

As per stats by McKinsey, modular construction techniques can reduce total construction time by 50%.

Sure, prefabrication looks great on the outside, but we can’t forget about the less exciting, yet super important, part: getting it all from point A to point B. Getting bulky components from factory floors to cramped city sites can make or break the budget, schedule, and even the viability of a project.

Source: Slabs Engineering

This article breaks down a head-to-head comparison between two modular heavyweights: 3D PPVC (Prefabricated Prefinished Volumetric Construction) and the long-standing 2D precast concrete. This analysis looks into the transportation and logistics challenges of both methods. We’ll show how one clearly offers efficiency advantages, but we also get that the other is still a perfectly good choice.

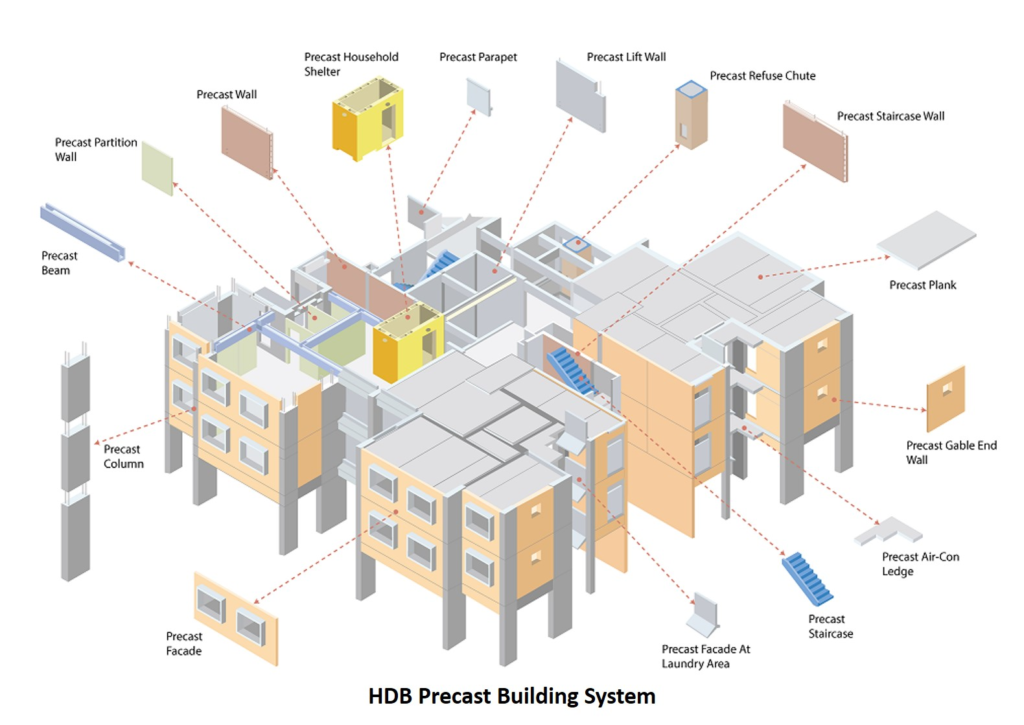

Fundamental Differences: 2D Precast Concrete vs. 3D PPVC

The difference between 2D and 3D PPVC lies in the appearance of the components and their assembly at the construction site. In 2D precast construction, the components received are planar elements, such as slabs and wall panels, which are fabricated in a factory and transported individually. Building a single floor with this method needs many truckloads, each carrying different flat elements that are then joined together on site.

In 3D PPVC systems, complete room-sized modules are made in the factory with all finishes, wiring, and plumbing inside. Each module arrives as a finished unit, so much less work is needed after delivery. One truck can bring a whole room ready to use, while the 2D one needs many deliveries for the same area.

Source: Gemini-generated image

Transportation Efficiencies of 3D PPVC

While the fundamental distinctions between 2D precast and 3D PPVC have been established in prior discussions, the transportation benefits of PPVC warrant particular consideration. Reduced trips, fewer lifts, decreased congestion, and enhanced quality position it as a superior option in urban construction logistics.

Optimized Trucking and Fewer Deliveries for Transportation

In Singapore projects, a single volumetric module can weigh between 25 and 40 tonnes, yet it consolidates the equivalent of many wall panels, slabs, and beams into one delivery.

By contrast, 2D precast often needs multiple truckloads for just a single floor segment. This consolidation cuts down fuel usage, transport costs, and the risk of damage during transit.

Reduced On-Site Handling and Crane Lifts

Each PPVC module is typically lifted once directly into position. This reduces time for adjusting or adding more pieces, just like in 2D PPVC.

The Tengah housing project in Singapore was handled by a Jaso J1400 tower crane that has the capacity of carrying up to 35 tonnes.

Source: Jason Tower Cranes

Urban Congestion Benefits

PPVC really cuts down on the number of trucks needed for deliveries, which helps ease traffic on busy city streets. In packed urban areas, deliveries often happen at night to steer clear of peak traffic and to get permits for really big loads. Plus, the quicker setup means roads and site entrances aren’t blocked by waiting trailers and cranes for as long, which is a huge plus in busy city settings.

Consistent Quality and Less Damage

Factory-finished PPVC modules are more resilient to damage.

At Singapore’s The Clement Canopy, this method boosted productivity by 72% (0.613 m² vs. 0.357 m² per man-day) compared to traditional projects.

Source: The Clement Canopy

This efficiency, along with less noise and dust on site, could really help Indian construction. They often deal with similar problems like weather damage and handling risks.

Transportation and Handling Challenges of 2D Precast Concrete

While 2D PPVC is pretty popular, it really brings a lot of logistical challenges with itself, especially in crowded urban areas. Some of these include:

- High Frequency of Deliveries: Constructing a high-rise building with precast panels requires multiple truck trips. A residential tower project may require hundreds or even thousands of deliveries, each transporting specific panels for various floors.

- Panel Fragility During Transit: Although precast panels are very strong once installed, they can be damaged during transport. Edges are especially prone to chipping, cracking, or spalling due to excessive vibration or improper handling. Therefore, careful packaging and handling are crucial.

- Requirement for Staging Yards: Dealing with precast elements on urban construction sites often comes with big logistical hurdles due to limited space. These projects need large staging areas to sort and store panels before they are installed. If there isn’t enough room on-site, it might mean using off-site staging yards, which bumps up transportation costs, making everything more complicated.

- Additional Crane Operations: Every individual precast element requires a separate crane lift. This increases the total number of lifts, extends the project timeline, and escalates the risk of accidents.

Precast concrete is great for low-rise or suburban developments, especially when there’s plenty of storage on site. But for those busy urban projects, it can be pretty expensive.

Logistical Complexities in Transportation of 3D PPVC Modules

Although 3D PPVC provides efficiency benefits, its bulky form presents a distinct set of logistical challenges.

Oversized Loads & Regulatory Hurdles

A major hurdle for PPVC modules in India is their tendency to exceed legal transportation dimensions.

According to the Ministry of Road Transport and Highways (MoRTH), a standard truck width is typically around 2.5 meters, whereas a residential PPVC module can easily be wider.

Transporting Over-Dimensional Cargo (ODC) necessitates extensive and time-consuming permits from state and local RTO authorities. This can prolong project planning by several weeks or even months.

Urban Infrastructure Constraints

The narrow, congested streets, sharp turns, low-clearance flyovers and bridges, and ubiquitous overhead power lines and wires pose real delivery hurdles. A single miscalculation can halt a delivery and cause major traffic jams, a common headache in cities like Mumbai, Delhi, or Bangalore.

Permitting and Route Planning

Getting permits for nighttime construction material deliveries is hard because there aren’t clear rules. This means logistics teams have to plan routes to avoid heavy traffic, which often requires expensive and complicated coordination with special escort vehicles and police.

Specialized Haulage

Transporting 3D PPVC modules involves more than just accounting for their weight.

Source: Alibaba

A standard trailer with a 40-ton load capacity can often handle the mass of a single module. However, the real challenges arise from the dimensions and geometry of these units. Oversized width, height, and length may exceed road clearance limits, making it difficult to navigate under bridges, through flyovers, or around sharp turns. In such cases, specialized low-bed or extendable trailers are required to ensure safe and compliant transport.

Mitigation Strategies: Best Practices in Modular Transportation

In order to take advantage of PPVC while minimizing its transport and logistics drawbacks, here are some best practices:

Pre-construction Route Surveys and Traffic Simulations

In India, oversized cargo like wind turbine blades and metro tunnel boring machines often face the same hurdles as PPVC modules. Companies like Larsen & Toubro (L&T) routinely conduct detailed surveys, checking for bridge load limits, flyover clearance, and sharp turns.

Staging Areas Near Sites

Buffer zones, or drop-lots, are effective in mitigating last-mile delays. For instance, the Delhi Metro utilized proximate yards for storage prior to the installation of precast segments.

Phased Delivery Schedules

Phased sequencing, a method that accelerates floor cycles, has already been implemented in India by companies such as Shapoorji Pallonji for their precast-heavy projects. This approach could be readily applied to Prefabricated Prefinished Volumetric Construction (PPVC).

Use of BIM and Digital Tools

Building Information Modelling (BIM) is useful for planning things like crane paths and delivery routes. Tata Projects used it to plan metro stations, avoiding clashes with power lines.

Deeper Comparison: Load Bearing & Non-Load-Bearing 3D PPVC

The practicality of PPVC is determined by transport and logistics. However, the decision between load-bearing and non-load-bearing systems is equally important. The practicality of PPVC is determined not only by transport and logistics but also by the choice between load-bearing and non-load-bearing systems. This decision is influenced by several project-specific considerations, such as seismic zone requirements, variability in local material availability, and the cost-sensitive nature of mass housing developments. These factors are not uniform across regions or project types and therefore need to be carefully re-examined in each context before finalizing the system selection.

Load-Bearing 3D PPVC:

- Structural Role: These modules serve as the main structural elements of a building, supporting both gravitational and lateral loads.

- Logistical Impact: Moving extra-large or over-dimensional cargo (ODC) is difficult because it requires special, powerful trailers and cranes. In India, it’s even harder due to strict rules and a shortage of these specialized vehicles.

- Project Example: The Light House Project (LHP) in Ranchi, part of the Government of India’s Global Housing Technology Challenge, uses 3D modular precast concrete. Moving large building parts from the factory to the construction site, and then carefully putting them in place, was a difficult task that needed a lot of planning to go smoothly.

Source: GHTC-India

Non-Load-Bearing 3D PPVC:

- Structural Role: These modules are not load-bearing. They are typically used for ancillary spaces like bathroom pods, MEP (Mechanical, Electrical, and Plumbing) shafts, and kitchens.

- Logistical Impact: While non-load-bearing units are lighter, their bulk means trailers usually reach dimensional capacity before weight capacity. Since transport costs are charged per trailer rather than per tonne, this creates an inefficient payload utilization — developers often describe it as “paying for transporting air.” For example, a 40-ton trailer may carry only a 12-ton bathroom pod but still incur the same freight charges as a fully loaded heavy module. This makes logistics planning, stacking strategies, and module size optimization critical for cost efficiency.

- Project Example: The use of pre-cast bathroom pods has become increasingly common in high-end Indian hotels and residential projects in cities like Mumbai and Pune. Companies such as Loom Crafts and Spartek manufacture and deliver these pods, which are then integrated into a conventional structural frame. While the pods are generally smaller than full PPVC modules, their dimensions often restrict how many can be loaded onto a single truck. In some cases, two pods can be transported together if size and stacking arrangements allow, but more commonly, each trailer carries only one pod due to road clearance and handling constraints. This means that although pods simplify on-site installation, their logistics efficiency varies case by case, depending on pod design and transport route conditions.

Source: Spartek

Key Takeaway

Choosing between these two PPVC systems really comes down to what the project needs structurally and how we can best manage the logistics here in India. A lot of developers are finding the non-load-bearing approach more practical because it nicely balances the benefits of prefabrication with the challenges of getting things around in our cities.

Expert Conclusion: Matching System to Context in Transportation

In conclusion, 3D PPVC is like getting a room delivered to your doorstep, fully built. It is fast, which means way less noise and mess on-site, and slashes the number of trucks clogging our already-congested roads. The biggest hurdle, though, is the sheer challenge of getting these massive “room-boxes” through tight city streets.

2D precast concrete is more like getting all the parts of a building in a kit. It gives flexibility, but it comes with a lot more deliveries and on-site assembly.

Ultimately, the decision isn’t about one method being inherently superior. Instead, it involves a strategic selection of the most suitable approach, one that aligns with the specific location and challenges of each project.