With rapid technological advancements and a growing emphasis on sustainability and efficiency in the construction industry, new methods are continually emerging to redefine the landscape of building and design. One such groundbreaking approach is 3D Precast Prefinished Volumetric Construction (3D PPVC), a construction method that promises to revolutionize traditional techniques.

What is a 3D Precast Prefinished Volumetric Construction (3D PPVC)?

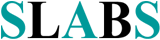

3D PPVC is a highly sophisticated building approach integrating precast concrete techniques, 3D design, and modular construction principles. It refers to a design of a building in which separate three-dimensional modules are built in a factory, outfitted with all necessary fittings and fixtures, and then shipped to the construction site, where they are assembled and connected structurally, as well as to the plumbing and electrical systems.

Courtesy: Housing and Development Board, Singapore

Advantages of 3D PPVC

Some of the advantages are-

- 3D PPVC and Sustainability

One crucial advantage of 3D PPVC technology is its inherent sustainability. Streamlining the construction process and reducing waste offers an environmentally friendly alternative to traditional construction methods. Factory-based precasting processes optimize material usage, minimizing waste production. Furthermore, the reduced need for on-site activities reduces carbon emissions, particularly those related to transport and machinery.

It’s also important to note that 3D PPVC promotes the idea of ‘constructability.’ This concept focuses on optimizing construction processes to reduce environmental impact, improve safety, and maximize efficiency.

- Safety and Quality Assurance

Safety is a paramount concern in any construction project, and 3D PPVC’s inherent characteristics contribute significantly to improved safety outcomes. The shift of labor-intensive tasks to the controlled environment of a factory minimizes the risk of accidents associated with traditional on-site construction.

Quality assurance is another area where 3D PPVC shines. The factory-based precasting process allows for more stringent quality control measures. It eliminates the variability associated with on-site construction conditions, ensuring a higher standard of quality and consistency in the construction components.

- Reduced Labour Requirement

Given the high level of prefabrication involved in 3D PPVC, fewer on-site workers are required, which is a benefit in regions where labor cost is high, or there is a shortage of skilled workers.

- Flexibility

3D PPVC modules can be disassembled and reassembled, allowing for layout changes and flexibility in building design. This can be particularly useful in projects where future adaptability is a requirement.

Limitations of 3D PPVC

Despite the many advantages of 3D Precast Prefinished Volumetric Construction (3D PPVC), there are also significant challenges associated with its implementation. Here are some of the main obstacles that may need to be addressed:

- High Initial Investment:

The upfront costs of adopting 3D PPVC technology can be significant. This includes the expense of purchasing specialized machinery, setting up controlled factory conditions, and investing in software for 3D design and planning. The setup costs, and ongoing upkeep of a precast plant close to or on-site are expensive. Large-scale projects or construction speeds of 1 million square feet to 3.5 million square feet per year are necessary for this building style. About 15–20 individual parts make up a 2D precast flat, which means more cranes are needed for an erection, driving up the cost. Small and medium-sized enterprises may particularly find this prohibitive.

- Skilled Labor and Training:

The use of 3D PPVC technology requires a workforce with specialized skills. Traditional construction workers may need extensive training to adapt to the new systems, and there may be a need for more skilled labor available for this work. This, in turn, can lead to a higher labor cost, at least initially.

- Regulatory Hurdles:

The construction industry is heavily regulated, and new technologies such as 3D PPVC often face regulatory obstacles. Local building codes may only partially accommodate the new methods and systems, requiring time-consuming and costly processes to obtain the necessary permissions and certifications.

- Logistics and Transportation:

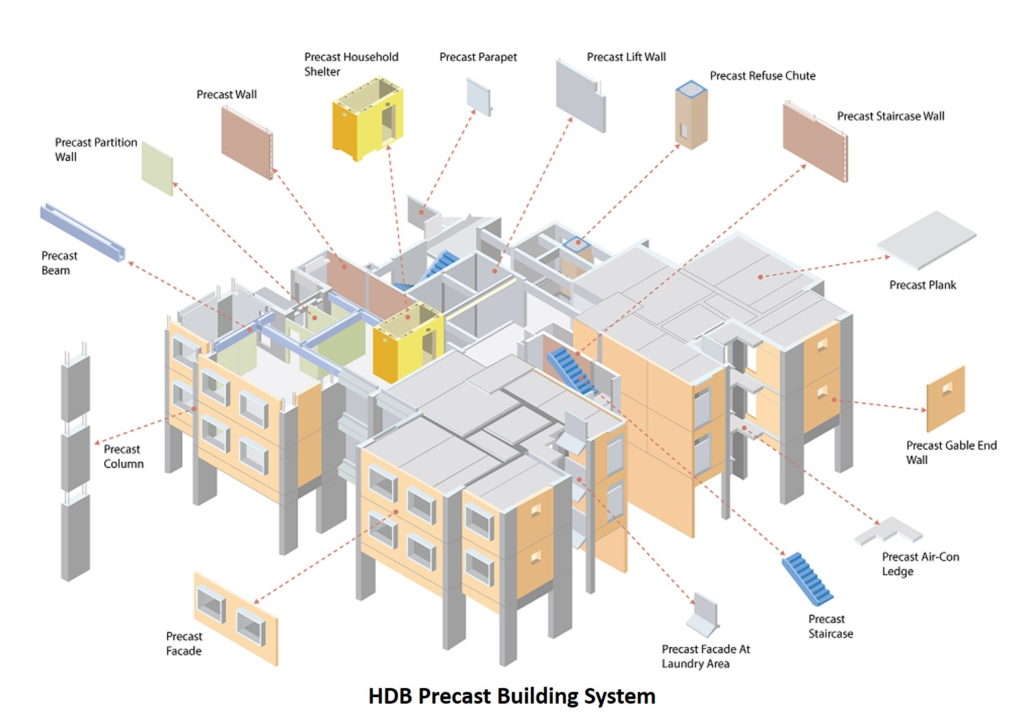

Logistical issues can arise as the building modules are fabricated off-site and transported to the construction site. These modules are typically large and heavy, requiring special transportation and handling methods. Site access and local regulations concerning oversized loads could pose significant challenges.

Courtesy: Housing and Development Board, Singapore

- Design Limitations:

While 3D PPVC offers significant advantages in terms of efficiency and quality control advantages, it can also limit design flexibility. The system works best with simple, repetitive designs and may not be suitable for more complex or unique architectural projects.

- Adoption and Change Resistance:

As with any new technology, resistance to change can be a significant barrier. Convincing stakeholders, from architects and engineers to construction workers, to embrace new methods and abandon established practices can take time and effort. This necessitates effective change management strategies and extensive education and training initiatives.

Present Scenario of 3D PPVC

The 21st century has seen the rise of remarkable innovations in the realm of Precast Prefinished Volumetric Construction (PPVC), featuring advanced 3D molds, transformative turners, and highly-efficient circulation lines. This trail of revolutionary projects, from Uruguay to the United States, demonstrates this technology’s remarkable growth and acceptance worldwide.

In 2017, Singapore made its mark by using 3D molds for making precast bathroom pods. This was a key step forward in the evolution of this construction technique.

In 2018, Singapore was again in the spotlight for using 3D molds and 180º turners to create 3D elements. This demonstrated Singapore’s commitment to embracing and furthering this new technology.

By 2020, the technology had gained wider acceptance. Malaysia started using the 180º turner for 3D elements. At the same time, Saudi Arabia began using 3D molds, and Hong Kong introduced 3D molds for bathroom units.

The momentum continued into 2021, with France adopting the use of 3D molds and Singapore further showing its leadership by using 3D molds specifically for PPVC.

In 2022, the technology saw a major expansion. Canada started using the 180º turner for 3D elements, while Sri Lanka and the USA adopted 3D molds for PPVC and bathroom units. The USA also introduced a circulation line for finishing the work of Prefabricated Bathroom Units (PBUs).

This timeline clearly shows how 3D PPVC technology has steadily grown in popularity and use worldwide. With each year, more countries are embracing this innovative approach to revolutionize their construction industry.

Conclusion

3D PPVC is a transformative technology that holds the potential to revolutionize the construction industry. It promises greater efficiency, improved quality, enhanced safety, and increased sustainability by merging the principles of precast construction, 3D design, and modular building. As our world grapples with the dual challenges of urbanization and climate change, technologies like 3D PPVC represent a significant stride towards a sustainable and resilient future for the construction industry.

References

- https://www.moldtechsl.es/en/present/industrialized-construction-ppvc/

- https://www.moldtechsl.es/en/projects/equipment-for-the-production-of-3d-elements/

- https://www.hdb.gov.sg/about-us/research-and-innovation/construction-productivity/prefabrication-technology

- https://www.bft-international.com/en/artikel/bft_Prefabricated_Prefinished_Volumetric_Construction_mold_provided-3747925.html

- https://www.structuremag.org/?p=17470

- https://www.nbmcw.com/product-technology/precast/the-3d-monolithic-volumetric-precast.html

- https://www.nbmcw.com/product-technology/precast/3d-modular-precast-prefinished-toilet-kitchen.html